Manufacturing & Testing

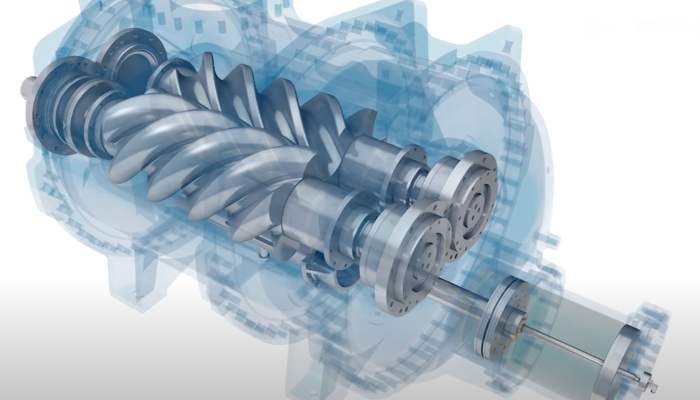

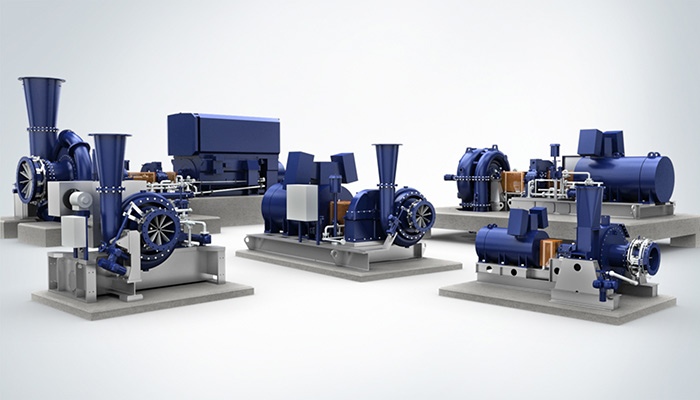

World leaders in manufacturing screw compressors.

Today in thousands of applications worldwide, Howden screw compressors provide high integrity, low maintenance solutions for liquid chilling, direct refrigeration and gas compression. Our comprehensive testing standards is key to remaining committed to manufacturing the highest quality compressors in the industry.

The industry’s largest and most versatile range of oil injected and oil free screw compressors are tested in our Renfrew centre, Scotland.

- Site Area (m²): 65,000

- Factory Area (m²): 10,500

- Quality ISO 9001:2015

- Health & Safety ISO 45001:2018

- Environmental ISO 14001:2015

- 5 Test Beds

The digitally enabled Test Suite - Transforming your equipment testing experience

Equipment testing is an essential part of purchasing a Howden Compressor. Many of our customers observe the compressor testing by traveling to Renfrew, from all over the world, to validate the performance and reliability of their product before being shipped.

Remote testing

The introduction of the new test studio allows the customers to witness the test of their equipment remotely, from anywhere in the world. The studio is equipped with live camera feeds and live trending screens showing the data in real-time, directly from the test bed. All of this data can be accessed on any smart device given there is an internet connection. Providing our customers with the option of remote testing eliminates the requirement to travel, reducing time and cost commitments, making the testing experience more convenient.

Transforming the test experience with Augmented Reality

Utilising state-of-the-art Augmented Reality (AR) technology allows for a truly transformative test experience. The Test Engineer will complete the live test whilst wearing a Microsoft HoloLens device. On the live video feed, the customer will watch the live test and with the addition of AR, the real-time data values will be augmented on top on the equipment. This provides the customer with the live test and the test values, all available on one screen.

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team