Chart Industries and Flowserve announce a merger of equals to create a differentiated leader in industrial process technologies. Learn More.

×

Howden

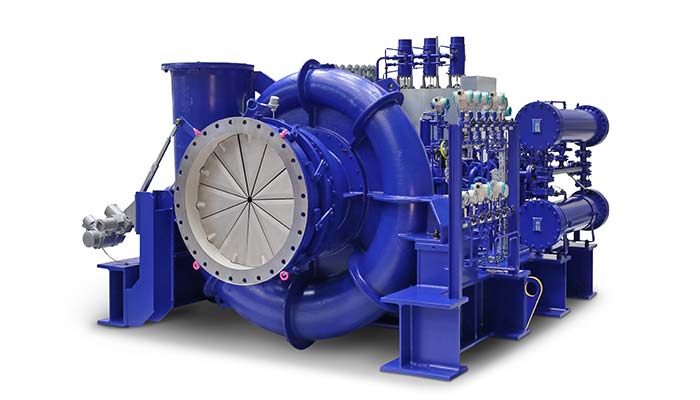

Howden provides mission critical air and gas handling products and services that our customers’ vital processes depend on. We help our customers increase their environmental and operational efficiencies and decarbonize their operations. We are advancing a more sustainable future.

We are Howden

Revolving Around You

For over 160 years, Howden has been at the forefront of developing engineered solutions for the needs of industrial processes. Today our technology and worldwide engineering expertise and services optimize our customers' vital processes throughout the world. This is ensured through a strong global network of experts, formed from responsive local service and delivery teams in more than 100 countries, who are familiar with local requirements and challenges.

The latest chapter of our history is as a Chart Industries company, having been acquired in 2023. The strategic acquisition expands Chart's offering of products and solutions across the Nexus of Clean™ - clean power, clean water, clean food and clean industrials. The complementary nature of the equipment and solution portfolios results in a differentiated offering across many industries benefiting customers by enabling a more complete solution to their operational and engineering needs.

Video Library

Product & Brand Portfolio

Use the carousel below to navigate straight to our principal product pages. Continue to scroll to learn more about our business.

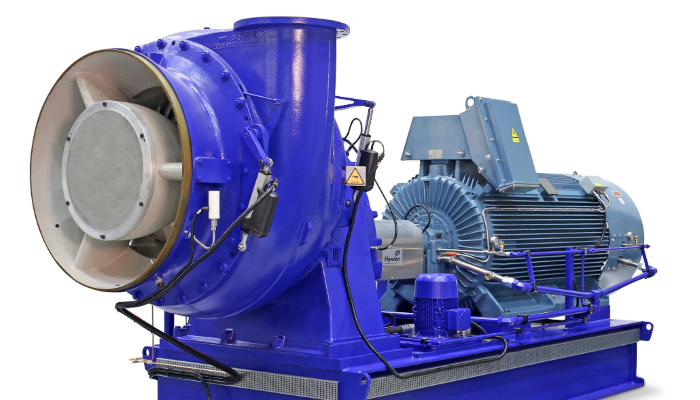

Steam Turbines

Steam turbines designed for a variety of applications from 1 MW to 40 MW and inlet pressures to 70 bar; condensing, mixed pressure and back-pressure. Our steam turbines provide over 1000 MW of installed power in Waste to Energy Power Plants and we have in excess of 500 machines installed in the cane sugar industry.

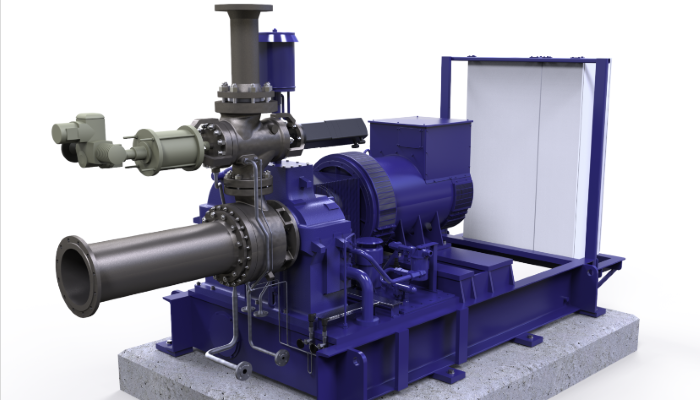

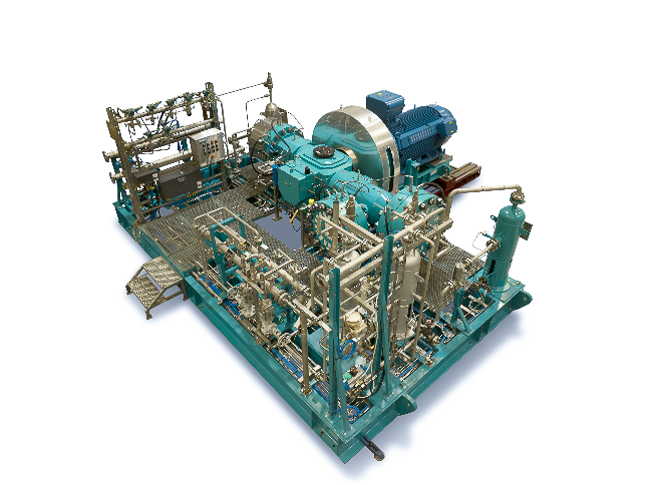

Reciprocating Compressors

Reciprocating gas compressors rated to 20MW and operating between 260 and 1,000 rpm. Peter Brotherhood range covers a wide spectrum of gas mixtures, including corrosive and hazardous gases. Designed to operate at low speeds with variable strokes to give maximum reliability, smooth operation and low wear, for maximum service life.

Steam Turbines

Steam turbines designed for a variety of applications from 1 MW to 40 MW and inlet pressures to 70 bar; condensing, mixed pressure and back-pressure. Our steam turbines provide over 1000 MW of installed power in Waste to Energy Power Plants and we have in excess of 500 machines installed in the cane sugar industry.

Reciprocating Compressors

Reciprocating gas compressors rated to 20MW and operating between 260 and 1,000 rpm. Peter Brotherhood range covers a wide spectrum of gas mixtures, including corrosive and hazardous gases. Designed to operate at low speeds with variable strokes to give maximum reliability, smooth operation and low wear, for maximum service life.

Steam Turbines

Steam turbines designed for a variety of applications from 1 MW to 40 MW and inlet pressures to 70 bar; condensing, mixed pressure and back-pressure. Our steam turbines provide over 1000 MW of installed power in Waste to Energy Power Plants and we have in excess of 500 machines installed in the cane sugar industry.

Aftermarket

Howden has developed the unique 4P (Parts, Presence, Precision, Prevention) concept to deliver faster and higher productivity with continuous technological innovation. That means quality products, training, and services designed and tailored to meet each custumer’s needs.

We offer Outage Solutions that bring together a wide range of technical expertise we reduce complexity, identify optimized scope solutions, and deliver within the tightest of timescales. With careful planning and risk management, we can avoid lost revenue by reducing the risk of future plant failure, maximising component life, and restoring and improving plant performance.

20173000

of leaking vent gas prevented

Emission Reduction

Our innovative EMISSIONGUARD™ TR² Packing Rings have prevented an estimated 20,173,000 Nm³ (693,144,000 scf) of gas from leaking through the vents of packing cases mainly in the petrochemical and natural gas compression industry. This reduction in emissions is equivalent to 60,500 metric tons of CO₂, which compares to 150,191,000 miles driven by an average gasoline-powered passenger vehicle.

Technical Library

View and download solutions brochures for some of our major markets.

Compressor Technology for Biogas

As the biogas industry continues to advance towards a more sustainable and energy efficient future, Howden screw compressors stand at the forefront of innovation revolutionizing the way biogas is process, upgraded and distributed.

Howden Select

Screw compressor configuration software for all process gas and refrigeration selections in a single unified platform.

Hydrogen Compression Solutions

Compression technologies are a key component in the hydrogen value chain and accelerate the energy transition.

Kühnle, Kopp & Kausch®

Howden range of Kühnle, Kopp & Kausch® single and multi-stage industrial turbo compressors.

Maintenance Partners by Howden (HMP)

Total solution aftermarket service partner maximizing the efficiency, longevity and safety of rotating and turbomachinery equipment. Servicing all Howden brands and 3rd party equipment.

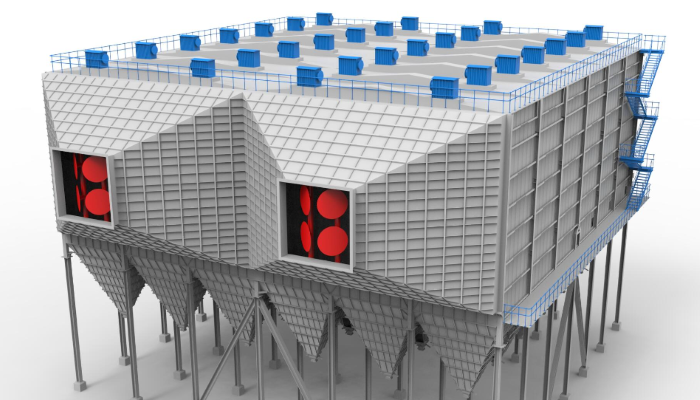

Solutions for the Cement Sector

Solutions for the Energy Recovery Sector

Solutions for the Metals Industry

Solutions for the Mining Industry

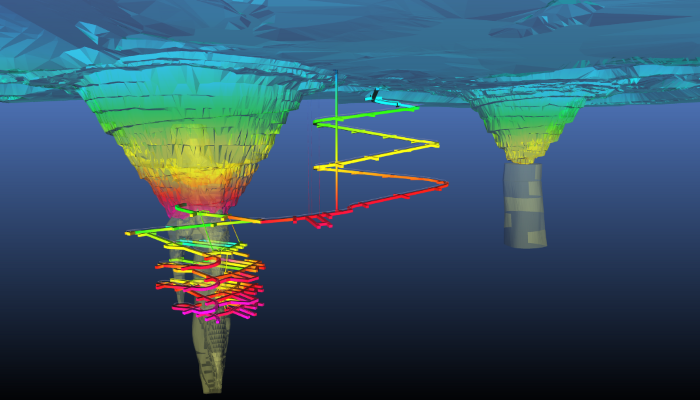

Solutions for the Oil & Gas Industry

Solutions for the Wastewater Sector

Spencer - Blowers and Vacuum Systems

Spencer's products include single and multi-stage centrifugal blowers, gas boosters, central vacuum systems, mobile vacuum units, separators, regenerative blowers, electrical control panels, tubing and fittings and vacuum accessories.

Spencer - Custom Blowers and Gas Boosters

The specialists for air and gas handling equipment in corrosive, toxic and harsh environments and applications, such as high temperature, high pressure and gastight requirements.

Spencer - Industravac Vacuum Units

Powerful, low noise, high efficiency vacuums maintain a clean operational environment for employees and visitors.

Spencer - Vortex Regenerative Blowers

Compact, lightweight design, wide performance range, proven long term reliability, oil-free air delivery, reduced heat and noise with application flexibility.

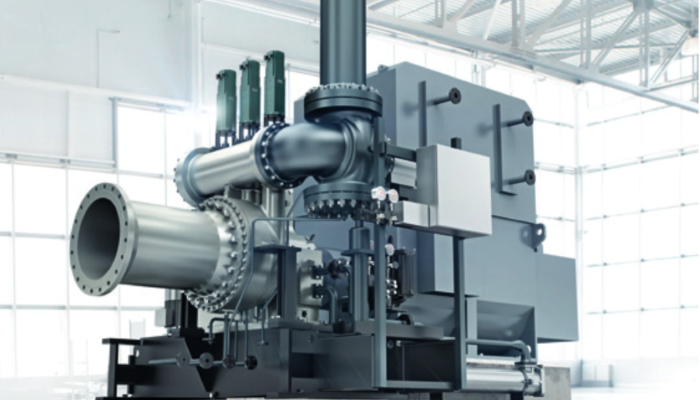

TURBLEX Centrifugal Turbo Compressor

TURBLEX compressors are engineered and built according to plant specifications and consume significantly less energy compared to other compressor designs.

TURBLEX/HV-TURBO - Wastewater Aeration

TURBLEX/HV-TURBO compressors are significantly more energy efficient compared to other compressor designs used for biological effluent treatment in municipal and industrial sewage plants.

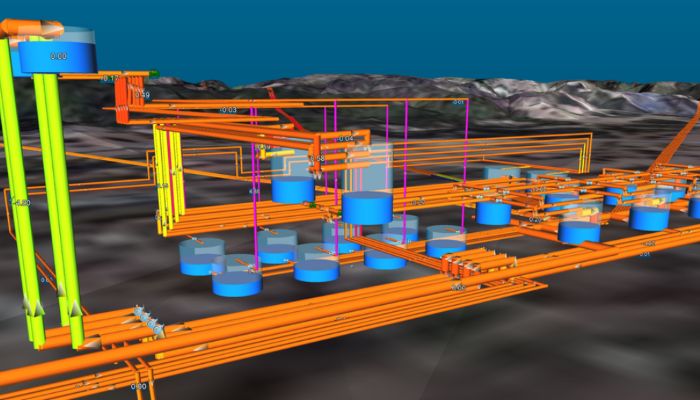

FLNG Compression

Howden screw compressors have been selected for a number of FLNG projects for their compact design, high performance and reliability.

Mine Ventilation and Cooling

Combining the air and gas handling products and mining experience of Howden with Chart's cryogenic expertise creates a unique opportunity for enhanced, efficient cooling solutions for mines. Article first published in Engineering News & Mining Weekly.

Diaphragm Compressor Maintenance Parts

Howden recommended maintenance spare part stocks for Burton Corblin diaphragm compressors.

Diaphragm Replacement Instructions

Storage and installation instructions for replacement diaphragms for Burton Corblin compressors.

Diaphragms for Burton Corblin Compressors

Maintain the integrity of your valuable assets with Howden OEM parts.

Dynalim Limiter

Set's the compressor's maximum discharge pressure.

Measuring Kit - Limiter Setting Point

An accurate hydraulic limiter setting is critical for the efficiency and reliability of diaphragm compressors.

Valves for Burton Corblin Compressors

Maintain the integrity of your valuable assets with Howden OEM parts.

Contact Howden

To send an enquiry, submit an RFQ, find our locations or join our team, click the Contact Us button.Telephone +44 141 885 7500

Contact Chart

Thank you for your interest in Chart's products and services.

Your request has been received and a member of our sales and customer service team will respond shortly.

Please open privacy settings and Accept All Cookies to use our "Email an Inquiry" feature.

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team