Articles

Learn more about how our products and services help customers just like you on a daily basis.

It’s only a little bit of dust, it can’t hurt me.

As a miner, construction worker, or oil & gas engineer you might be handling seriously heavy machinery and equipment day in and day out, so a little bit of dust may seem trivial.

But construction dust is much more than just a nuisance - it can seriously affect your health and certain types over time can even kill.

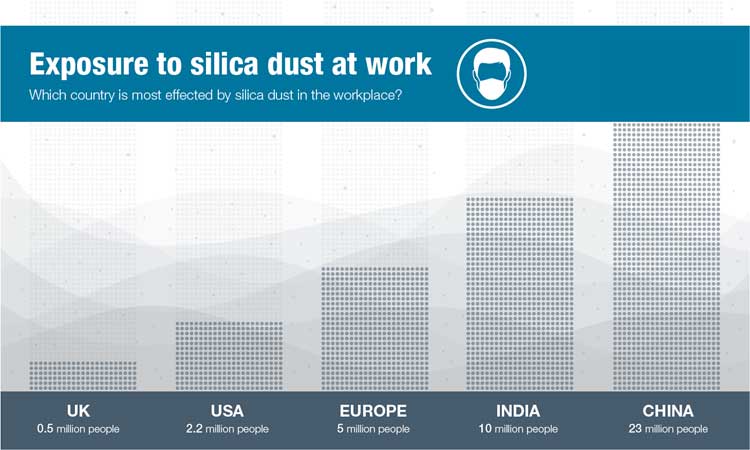

Respirable crystalline silica dust is one such killer - and with more than 2 million workers being exposed to silica dust every year in the workplace it is vital that everyone involved understands the risks and what can be done to prevent irreparable harm.

To get scientific about it ‘silica’ is a chemical compound formed from silicon and oxygen atoms. It comes in two forms; hazardous crystalline, or non-hazardous amorphous. And it is crystalline silica that causes all the trouble.

Crystalline silica is one of the most abundant minerals on earth, found in numerous naturally occurring materials such as rock, sand, stone, clay, and gravel.

These materials are the fundamental building blocks used to make building and landscaping materials such as bricks, tiles, roof slate, concrete, glass, ceramics and some plastic composites. Silica is also present during many common construction tasks such as excavating, mining, quarrying, and tunnelling.

Therefore silica is found widespread across the mining, construction, and engineering sectors all throughout the world.

Left within its material, silica is safe. It is when it’s disturbed that the crystalline silica becomes one of the most common workplace hazards.

Respirable crystalline silica is the dust that is released from the silica-containing materials during high-energy operations such as sawing, cutting, drilling, sanding, chipping, crushing, or grinding.

These very fine particles of the crystalline silica are now released into the air becoming respirable dust. Common scenarios where people may be exposed to respirable crystalline silica dust include abrasive blasting, mining and excavating, cement, steel and ceramic production, and many many more.

Miners often extract high-silica-content rock from the coal seam or the surrounding strata. Large quantities of silica dust can be generated during cutting and can become entrained in the ventilating air, which can carry the dust to the breathing zones of mine workers.

High levels of dust can be produced when cement is handled, for example when emptying or disposing of bags. Scabbling or concrete cutting can also produce high levels of dust that may contain silica.

Find out more about Howden's Centrifugal Fans used during cement production

Silica dust is very fine, much smaller than a tiny grain of sand found on a beach. This is what makes it so easy to inhale.

If you look at the full stop at the end of the previous sentence, that is around 200-300 micrometres in diameter. Whereas the respirable crystalline silica particle is only 5 micrometres in size.

If inhaled it can create a health hazard all the way from simple and instant irritation to life-changing and often life-threatening lung diseases.

Crystalline silica is a designated known human carcinogen meaning it is a definite cause of cancer in humans. Once you breathe it in it can go deep into your lungs and stay there - permanently scarring and damaging the lung tissue.

Howden’s VentSim DESIGN is an underground mine ventilation simulation software package designed to model and simulate ventilation, airflows, pressures, heat, gases, financials, radon, fire, and many other types of ventilation data from a model of tunnels and shafts.

Breathing this dust over a long period of time can eventually lead to life-changing and very serious lung diseases such as emphysema, bronchitis and silicosis. As well as lung cancer, kidney disease, and chronic obstructive pulmonary disease (COPD).

The chances of developing these diseases increase with higher and longer durations of exposure. The most at risk to develop these diseases are miners, construction workers, and oil & gas engineers that are often performing the tasks or processes that release the dangerous respirable crystalline silica dust.

FACT: Approximately 2.3 million workers were exposed to silica dust in the workplace. Over 500 construction workers are believed to die from exposure to silica dust every year.

Silicosis is an incurable and irreversible lung disease that results from the inhalation of silica dust which inflames and scars the lungs causing shortness of breath, coughing, and over time it can be a potentially fatal condition resulting in death.

The common length of time for silicosis to develop when being exposed regularly is between 10 and 20 years. But, in some cases with extremely heavy silica exposure it can develop within a few months to a year.

Once the very fine silica dust particles are breathed in they go deep into the lung where it is attacked by the immune system. This causes swelling and a hardening of the lung tissue also called fibrosis, causing the lung tissue to become permanently scarred and no longer able to function properly.

The symptoms of silicosis may take years to develop, even after you have stopped working with silica dust. They are irreversible and will continue to get worse the longer you are exposed.

The main symptoms of silicosis are:

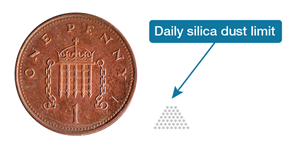

The typical exposures to silica in the building and construction industry are required by law to be limited to a maximum exposure of 0.1mg/m3 with many countries restricting it further to 0.05mg/m3 or as low as 0.025 in some states of Canada.

To put into context the maximum daily silica exposure in comparison to a penny

Due-diligence is extremely important to prevent any health hazards relating to silica dust. Both the employers and the employees must fully understand what they are working with and what risks are involved.

In certain countries including Britain, it is the employer’s legal responsibility to carry out risk assessments where there is exposure to silica and to implement effective control measures where required.

Following the health and safety laws that are put in place is not only essential but life-saving. Note these laws and legislation can vary between countries, territories, and states.

In Britain, the Control of Substances Hazardous to Health (COSHH) is the most relevant. In other European countries, the Chemical Agents Directive is the main source of legal requirements.

There are other bodies such as The Occupational Safety and Health Administration (OSHA) and the Health and Safety Executive (HSE) that also layout guidelines and measures that should be followed.

As an employer there are three key things you need to do to help reduce or prevent exposure to workers:

This is where the employer must identify any risks and hazards from silica dust and ideally see if they can be eliminated, substituted, or failing that put controls in place to reduce any risk.

They must look at each of the following:

The aim is to eliminate or minimise the generation of silica dust or prevent the excessive breathing in of it.

For the most common construction tasks that generate high exposures to RCS, OSHA has provided a table of controls that an employer must fully and properly implement to maintain the exposure limits enforced - Table 1 – Specified Exposure Control Methods When Working With Materials Containing Crystalline Silica of the silica standard.

If a task is not on that list there are a number of common-place controls that can be implemented including:

Outwith these physical controls, all employees should also receive the correct training and be given information on the possible risks of crystalline silica exposure, the control measures and how to use them, and any requirements for health surveillance.

Now that the controls have been implemented to eliminate, reduce, or manage the silica dust exposure, the controls should be routinely checked and monitored to ensure they are effective.

This can be done by:

No matter what country, what task, or what workplace there is a duty of care for employers and workers to ensure that health and safety standards are implemented and upheld.

Howden fans play a key role in maintaining safe processes within mining, steel, and cement industries. From moving materials and collecting dust in the cement & steel manufacturing process or providing clean air to mines.

Howden’s VentSim Solutions including VentLog can help you quickly understand the conditions in any area of your mine and make necessary adjustments.